Refrigerated Container (Reefer) Monitoring with REFCON

Transporting cargo in modern reefers is a complex task. Loaded with delicate perishables or pharmaceuticals or chilled and frozen meats, seafood and shellfish requires careful monitoring of the container to ensure a safe and reliable journey from producer to consumer.

Supporting industry-standard ISO10368 technology & other vessel infrastructure standards, REFCON is the market leader in providing exception management for reefers at sea or in container terminals, enabling the reefer technicians to focus in on problems rather than routine monitoring of containers.

Together with Copeland’s ProAct™ Transport solution through our vessel subscription program, REFCON enables operations center monitoring of all reefer containers and cargoes at sea.

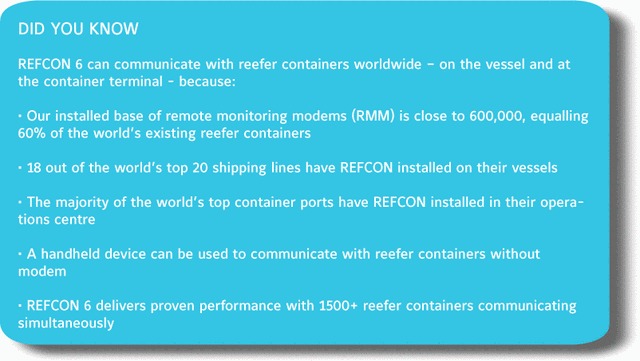

REFCON Industry Presence

Monitoring reefers at sea

On one of today’s massive container ships, there could be over 2’000 refrigerated containers carrying cargos from bananas to frozen tuna, with perhaps a container of high value pharmaceuticals amongst them, depending on the trade lane being serviced. On smaller vessels, the number of reefers may be fewer but the problem of monitoring them twice a day remains.

Either in rough weather in the Atlantic or on the long trans-Pacific voyage from Latin America into Asia, Copeland’s REFCON system allows the crew to manage the exceptions, rather than engage in routine twice-daily monitoring of all containers. Connecting to each container on the vessel regularly, REFCON alerts the crew to problem areas, whether cargo or equipment issues.