Unleash the Potential of CO₂ in Industrial Refrigeration

The Vilter transcritical and subcritical single-screw CO2 compressor platforms solve the industrial demands for more robust, reliable and simple CO2 alternatives. Based on high-pressure application experience in rugged, dirty and open-loop conditions in the renewable natural gas (RNG) industry, Vilter’s technological expertise is well-equipped to address today’s CO2 application requirements.

Advantages of the Vilter CO₂ System

Simplifying Industrial Refrigeration

- CO2 provides a solution to dynamic and uncertain regulations

- Integrates compressors, controls and oil management components to streamline system design

- Delivers high tonnage capacities with fewer industrial compressors

- Operates with fewer system parts — such as pipes, elbows and valves — which reduces potential failure and leak points while making system troubleshooting easier

- Removes the need for superheat which reduces system complexities and increases efficiencies

- Utilizes industrial-grade welded pipe versus brazed copper to reduce leak potential

- Avoids ammonia safety concerns and complexities associated with potential leaks

Enhance Reliability

- Reduces maintenance costs and prolongs equipment lifespan

- Improves uptime with fewer production shutdowns and delays

- Delivers lower total cost of ownership (TCO)

Purpose-Built for Industrial Rigors

- Supports high tonnage capacities

- Engineered with industrial-grade technology and componentry

- Withstands high transcritical CO2 pressures

- Meets load demands without requiring superheat

Meet Sustainability Goals

- Uses natural refrigerant CO2 with a GWP of 1 to help reach your sustainability goals

- Offers high heat reclamation potential (i.e., water heating, etc.)

- Reduces system footprint, requiring less installation space and saving facility resources

- Includes access to Vilter Lifecycle Services support and CO2 expertise to help your company solve application challenges

Simplicity For Industrial Applications

Shaping the Future of Industrial Refrigeration

Industrial CO₂ Compression Starts Now

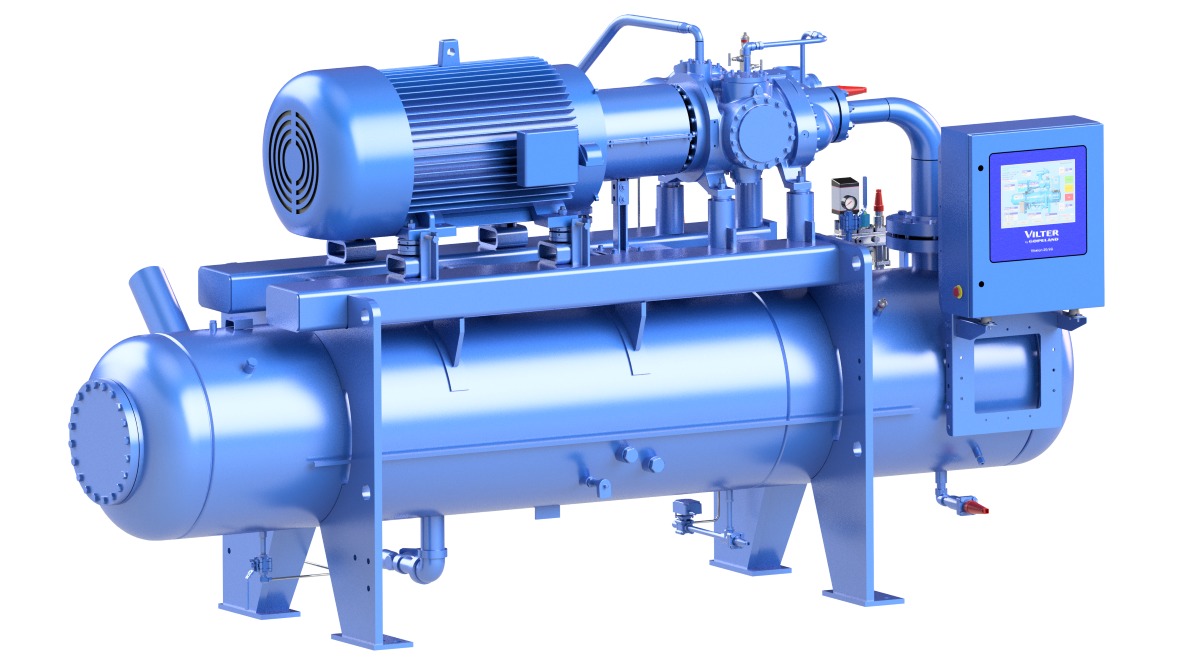

The Vilter transcritical CO2 single-screw compressor is purpose-built for industrial refrigeration. Individual and multiple compressor configurations can be leveraged to address a wide breadth of tonnage and temperature requirements.

One transcritical CO2 single-screw compressor can be applied in single-stage, higher-temperature applications, or in a CO2 two-stage configuration, which also utilizes the subcritical CO2 single-screw compressor for low-side loads.

Vilter offers solutions in single- and double-compressor configurations. A double-compressor configuration increases unit capacity while sharing common oil management and control systems to reduce costs and application footprint.

Subcritical CO₂ Industrial Compressor

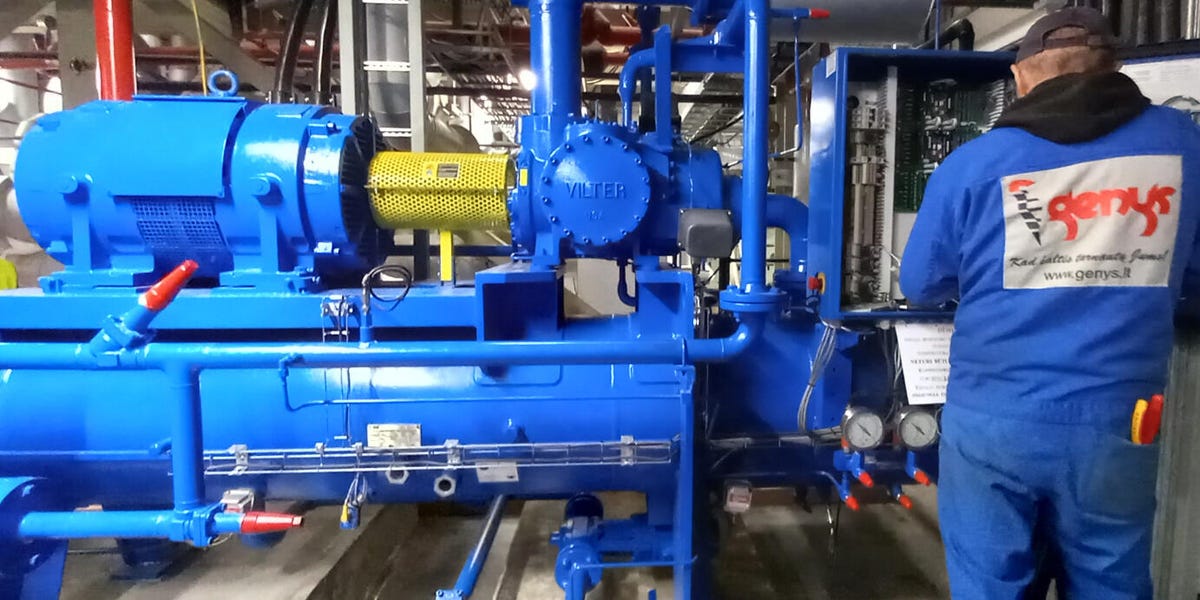

Part of Vilter’s industrial refrigeration CO2 solutions, purpose-built for subcritical applications to deliver reliability, simplicity, and longer system life. This model meets new sustainability goals with Vilter’s proven single-screw technology.

Transcritical CO₂ Industrial Compressor

Building on our legacy of innovations, Vilter has engineered one of the industry’s first transcritical CO2 screw compressor — purpose-built for heavy-duty industrial requirements and rated for CO2 transcritical pressures.

Innovating the Next Generation of CO₂ Industrial Refrigeration

The technologies used in industrial refrigeration are changing. For safety and sustainability reasons, operators are transitioning from ammonia and hydrofluorocarbon (HFC) refrigerants to refrigeration equipment rated for eco-friendly CO2 technologies. But current industrial CO2 solutions simply aren’t well-matched for the rigors of industrial applications...until now.

As a technology innovator in industrial refrigeration, Vilter is introducing one of the first generations of industrial CO2 compression solutions, purpose-built to deliver reliability, simplicity and longer system life — while leveraging a proven sustainable refrigerant.